Overhead Crane Radio Remote Control

Learn about Overhead crane remote control, its principles, features, functions, typical applications, and a guide to selecting the best supplier.

What is Overhead Crane Radio Remote Control?

An overhead crane, sometimes referred to as an “EOT crane” orbridge crane, is a common fixture in industrial production. Depending on the load requirements, these cranes are designed as either single girder or double girder structures and can be configured for single-speed or dual-speed operations. The application scenarios are varied and complex, such as:

- Controlling the Movement and Positioning of Overhead Cranes: The simplest function involves controlling the up-and-down movement. However, more often, we need to control movements in multiple directions—up, down, forward, backward, left, and right.

- Controlling the Speed of Overhead Crane Movement: Single-speed movements meet most application requirements, but in certain fields, we need dual-speed control for more precise movements, such as in precision machining workshops.

- Multiple Overhead Cranes Working Together: In specific scenarios, it is necessary to control multiple overhead cranes simultaneously for synchronized operation.

- Operator Positioning: Sometimes, we need to control the same overhead crane from different positions.

Thus, safe and precise control of overhead cranes is crucial in actual production. Traditional cranes often use wired controllers, but these are increasingly being replaced by wireless radio remote controls.

Why Choose Wireless Control for Overhead Cranes?

Operator Preferences

Different operators may be accustomed to various types of controllers—wired, wireless, button-operated, or joystick-operated. Wireless button-type remote controls are the most preferred.

Blocked or Crowded Areas

During cargo lifting, obstacles might block the operator’s path. In such cases, a wireless remote control becomes indispensable.

Better Visibility and Safety

Operators can choose the best position to control the crane, greatly improving visibility and safety.

Flexible Operation

Wireless remote controls can easily allow one remote to control multiple overhead cranes simultaneously or multiple remotes to control one crane. However, for safety reasons, we do not support simultaneous control of a crane by multiple remotes, allowing only one remote to be in control at a time.

Enhanced Safety

The wireless design enables operators to stay away from toxic, radiation-prone, high-heat, high-pressure, or other hazardous environments. Moreover, the absence of cables significantly reduces risks of electric shocks and tripping.

Increased Work Efficiency

The convenience and flexibility of use greatly enhance work efficiency.

Reduced Production Costs

Efficiency improvements and the elimination of the need for dedicated crane operators significantly reduce production costs.

How Does an Overhead Crane Remote Control Work?

An overhead crane remote control system consists of a transmitter and a receiver. The transmitter sends signal commands via radio waves, which the receiver interprets and executes.

If you want to learn more about the principles and knowledge of radio remote controls, click on the following page: “Radio Remote Control.”

Installation and Use of Overhead Crane Remote Controls

Installing and using overhead crane remote controls is straightforward and does not require extensive technical knowledge. TeleCtrl’s Industrial Remote Controls are comprehensive and highly compatible, allowing easy integration with most overhead crane control cabinets or PLC systems.

Click “Comprehensive Guide to Installing and Wiring Industrial Radio Remote Controls” to learn how to install industrial remote controls.

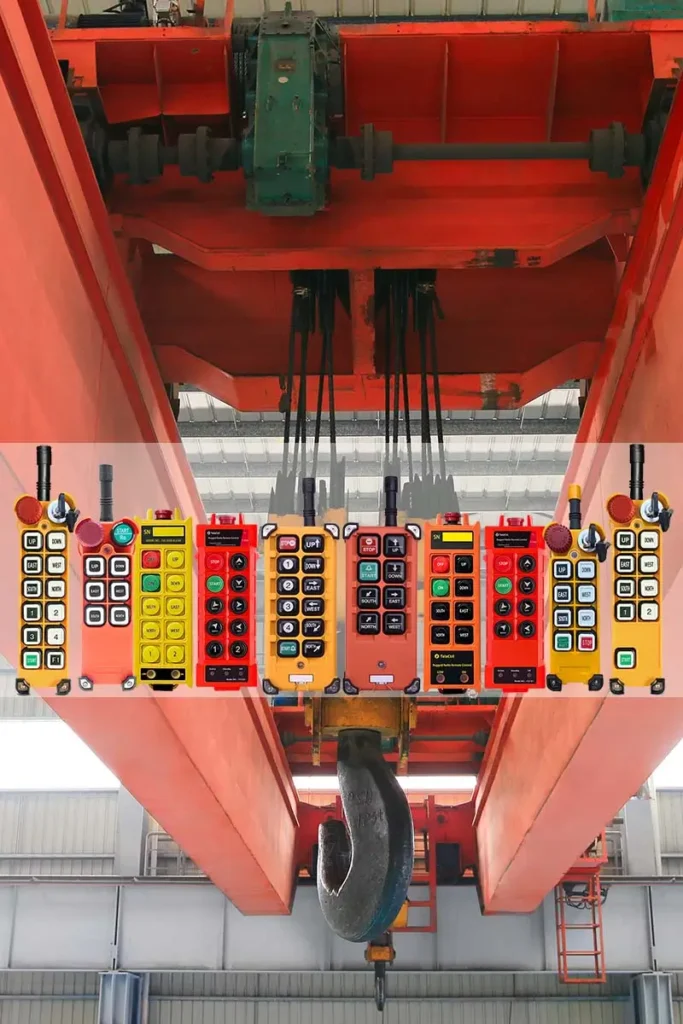

How to Choose an Overhead Crane Remote Control

The market offers a wide array of industrial remote controls. They are generally categorized into button-type and joystick-type controls. Joystick controls are suitable for complex overhead crane operations. Button-type remote controls vary in the number and function of buttons based on application complexity. Depending on user preferences, they may feature internal or external antennas. Different regions have varying safety standards and usage requirements, so safety features also vary. If you are unsure which remote control to choose, contact TeleCtrl for professional guidance.

Why Choose TeleCtrl Overhead Crane Remote Controls?

As one of the world’s largest industrial remote control manufacturers, TeleCtrl produces a wide range of commonly used remote controls. Supported by strong production capacity and supply chains, TeleCtrl products offer excellent quality and competitive prices, backed by comprehensive technical support and after-sales service.

Additionally, TeleCtrl provides diverse and personalized customization services to meet customer needs. To learn more about TeleCtrl’s customization services, click “Custom Radio Remote Control.“

Related Products

Case Studies

TeleCtrl will regularly share successful case studies of explosion-proof industrial remote controls in real-world applications to help you better understand their advantages and effectiveness.